Our jobs

For the execution of custom parts based on designs or in co-design, Cassetto employs the following process.

LASER CUTTING

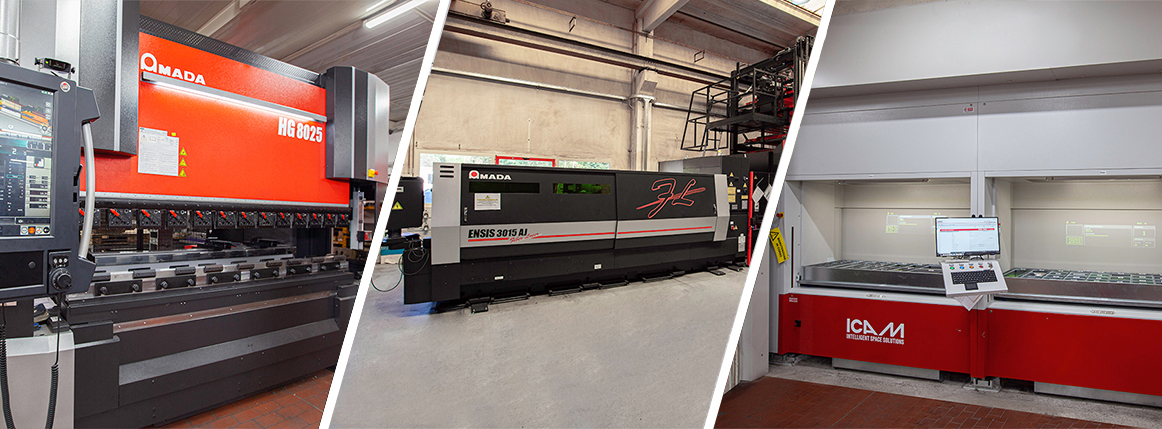

Execution of sheet metal cutting with thicknesses ranging from 0.5 mm to 25 mm using the following machines:

- Amada 3000W Fiber Laser “ENSIS 3015 AJ” + tower automation “ASLUL 3015”

- Amada 6000W Fiber Laser “ENSIS 3015 AJ” + tower automation “ASLUL 3015”

CNC BENDING

Cassetto uses machines of various sizes for air bending, including undercuts. The machine fleet consists of SCHIAVI and AMADA press brakes that cover bending up to 3000 mm in length.

CNC MACHINING

TURNING CENTRE

– Lathe OKUMA Genos L200E-M equipped with bar charger Top Automazioni

– Automatic turret for 12 motorized tools

– Range of works bars length 3000mm and diameter from 12 to 80mm

MACHINING CENTRE OKUMA GENOS M460R CNC

– Milling machine Okuma Genos M460R CNC 3 axis

– Automatic store for 32 tools

– Range of works: table 800×500

MACHINING CENTRE HARTFORD 5A-650F CNC

– Milling machine HARTFORD 5A-650F CNC 5 axis

– Automatic store for 32 tools

– Range of works: table 650x650x400 (axis Z)

ROLLING CNC

The process is permitted by a new machine technologically in step with the times which allows great repeatability.

TIG/MIG MANUAL AND ROBOTIC WELDING

The assembly process is carried out both manually with 8 workstations and robotically at 2 stations equipped with ABB anthropomorphic robots and rotary tables, using state-of-the-art welding machines with Industry 5.0 technology.

PROJECTION WELDING

We’ve at our disposition 3 projection welding machines.

SANDBLASTING AND TUMBLING

These processes are performed before the painting and permit to have clean parts and without cutting oxide.

ELECTROSTATIC POWDER COATING

We have two powder coating systems (one installed and tested in March 2024) with three-stage washing and rinsing, two coating booths on each system for primer and topcoat application with quick color change capability.